When venturing into custom apparel printing, understanding DTF transfer size is crucial for achieving stunning results. Direct-to-Film (DTF) printing has emerged as a game-changing technique, allowing for intricate designs and vibrant colors on garments. However, selecting the right transfer size can make or break your project, as it directly impacts design placement and visibility. In this guide, we’ll break down essential tips for choosing DTF sizes to ensure your apparel stands out. With a focus on different transfer techniques, we’ll equip you with the knowledge needed to create eye-catching pieces that resonate with your audience.

Custom apparel printing is more than just a trend; it’s an art that involves understanding dimensions and design intricacies. By exploring various DTF transfer dimensions, you can significantly elevate the aesthetic of your printed garments. The world of Direct-to-Film transfers offers versatility in application and creative freedom, enabling designers to play with size and placement for maximum impact. This article aims to guide beginners through the complexities of selecting the appropriate DTF transfer sizes, ensuring they can confidently navigate the mechanics of this innovative printing technique. So, let’s dive deeper into the nuances of DTF transfers and learn how to make informed choices that enhance your custom designs.

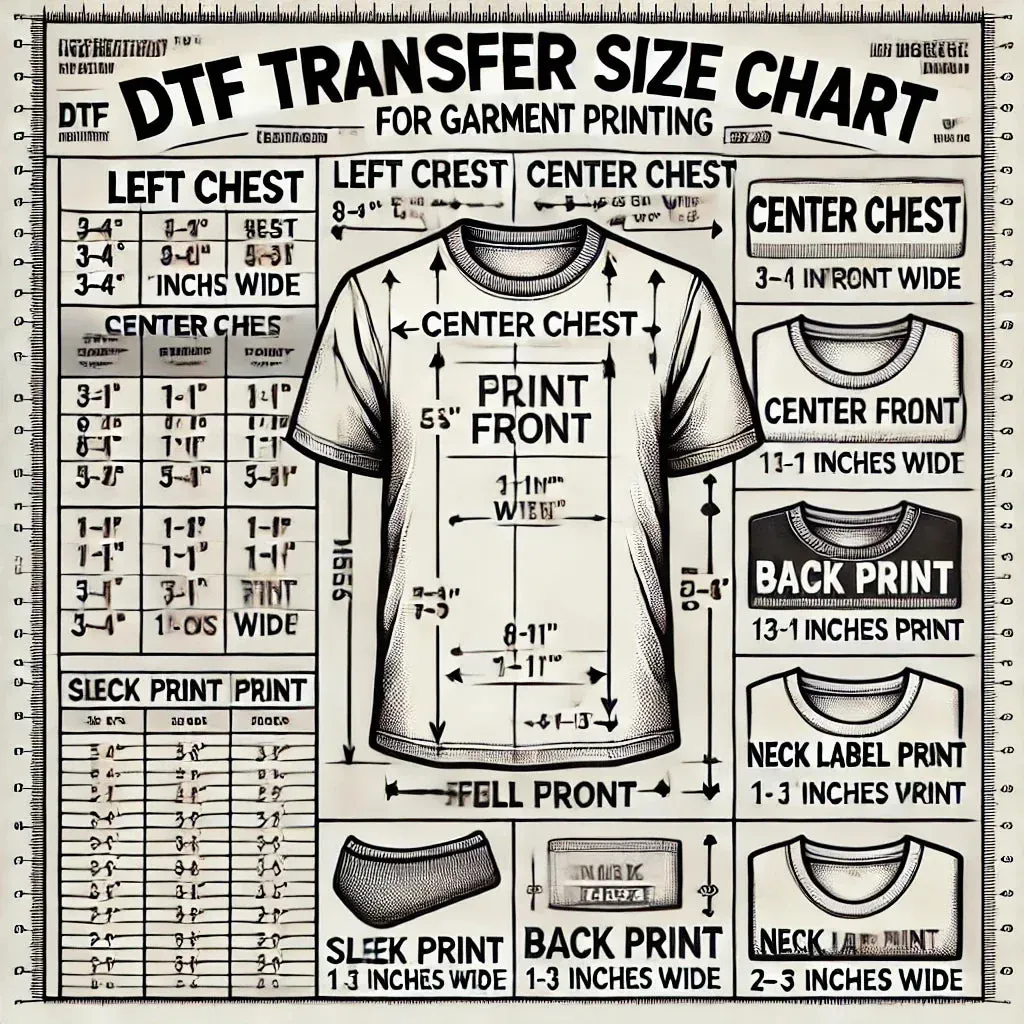

Understanding DTF Transfer Sizes

When embarking on your Direct-to-Film (DTF) printing journey, one of the first considerations you should address is the size of the transfer. The choice of size can dramatically impact not only the aesthetic appeal of your printed designs but also their practicality. For example, larger transfers might be necessary for hoodies and jackets, while smaller designs may serve well on T-shirts or caps. Understanding the variations in DTF transfer sizes is crucial for achieving the best result on different types of garments, ensuring that your art resonates well with the fabric.

Moreover, the ideal DTF transfer size can vary by the specific style of clothing you’re working with. For an optimal visual presence, it’s advisable to adhere to the general size guidelines, which typically suggest using a **12″ to 14″** transfer for standard t-shirts and sizes ranging from **14″ to 16″** for hoodies. This approach takes into consideration both the garment mechanics and aesthetic balance, allowing the designs to display as prominently as intended.

Choosing the Right Size for Different Garments

Selecting the appropriate DTF transfer size requires careful considerations of garment type and desired design placement. For instance, when printing a design meant for the front of a T-shirt, a transfer size of **11″ x 14″** might be suitable. In contrast, back designs will often require larger dimensions, such as **16″ x 20″**, to ensure the complete artwork is showcased without feeling cramped.

Additionally, it is essential to consider where designs will be positioned on the garment. A logo on the front breast, for example, typically requires a different size than an expansive artwork featured dramatically across the back of a shirt. Proper sizing not only enhances aesthetic appeal but also supports the garment’s overall fit, ensuring your customer feels comfortable and looks great.

Proportions and Aesthetics: Finding the Right Balance

The aesthetic value of custom apparel relies heavily on how well the design proportions blend with garment size. An oversized DTF transfer on a fitted shirt can detract from the shirt’s style, while small transfers on an oversized hoodie may visually appear abnormal. The synergy between transfer size and garment dimensions is integral; achieving balance will determine the success of your printing endeavor.

To maintain a coherent look, strive for a proper balance between design size and garment type. For example, a transfer that spans the entire back of a hoodie can create a striking visual impact, while the same size might overwhelm a smaller T-shirt. Thus, taking the time to analyze and test different proportions will contribute significantly to the successful execution of designs.

Experimentation: Finding Your Ideal DTF Transfer Size

For beginners navigating the world of DTF printing, experimentation is key in determining which transfer sizes produce the most visually appealing results. Each fabric responds differently to the printing process; therefore, testing a range of sizes can lead to discovering the ideal specifications for your specific printing projects. Small-scale practice runs will help gauge how various sizes influence print clarity and color vibrancy on different materials.

By keeping a diverse stock of transfer sizes, you can tailor your prints to suit specific projects and customer demands. This flexibility not only allows you to perfect your craft but also prepares you to meet varying client requests with confidence, ensuring every piece produced staying true to your brand’s standards.

Design Software: A Key to Effective Transfer Sizing

Utilizing graphic design software is fundamental when preparing your DTF artwork. Programs such as Adobe Illustrator or CorelDRAW provide robust tools that enable you to accurately resize and export images tailored to your selected DTF transfer size. By undertaking this digital prep work, you can streamline the production process and ensure high-quality printing.

Starting with a clear definition of the intended transfer size during the design phase is pivotal to avoid potential errors later on. Moreover, keeping your images at a high resolution—ideally around **300 DPI**—will ensure that your prints maintain their clarity and vibrancy even after application, enhancing the overall quality of your finished product.

Selecting Compatible DTF Materials for Success

Choosing the right materials for your DTF printing process extends beyond just the transfer film—it also encompasses the type of ink you’ll be using. Compatibility between your designs, transfer size, and materials is critical for ensuring durability and color vibrancy. Different transfer films have varying capacities and optimal sizes, which can drastically affect the final outcome of your printed apparel.

Investing in high-quality inks that are designed for DTF printing will also yield better results. Cheap or incompatible inks can lead to faded colors or designs that wear off quickly. By prioritizing material compatibility, you’ll ensure that your custom apparel not only looks good upon delivery but remains vibrant and intact through the wear and washing process.

Frequently Asked Questions

What is the ideal DTF transfer size for T-shirts?

When choosing the right DTF transfer size for T-shirts, the ideal range is generally between 12″ to 14″ wide. This size allows for optimal visibility and clarity of designs while maintaining a balanced look on the garment.

How does the garment type influence DTF transfer size selection?

The type of garment plays a crucial role in selecting the proper DTF transfer size. For example, hoodies typically require larger transfers, usually around 14″ to 16″ wide, to ensure designs are prominently displayed without appearing cramped.

What DTF transfer size should I use for a large back design?

For large back designs, a DTF transfer size of 16″ x 20″ is recommended. This size provides sufficient space for intricate details and helps the design stand out effectively on larger apparel like jackets or hoodies.

Can I use the same DTF transfer size for different placements like sleeves or chest?

No, different placements require different DTF transfer sizes. For instance, smaller logos on sleeves may use an 8″ x 10″ transfer, while designs on the chest may fit better with an 11″ x 14″ size to maintain proportion and aesthetic appeal.

What are some key DTF transfer tips for beginners?

For beginners, it’s essential to experiment with various DTF transfer sizes and placements. Additionally, utilizing graphic design software to set transfer dimensions before creating artwork can minimize resizing issues later in production.

How important is testing DTF transfer sizes before final printing?

Testing different DTF transfer sizes is critical for achieving the best print quality and visual appeal. Each fabric responds uniquely, so experimenting helps ensure the final product meets quality standards and enhances the customer’s satisfaction.

| Key Considerations | Details |

|---|---|

| Garment Type | Different garments require different transfer sizes. T-shirts typically use transfers between 12″ to 14″ wide, while hoodies may need 14″ to 16″ wide transfers. |

| Design Placement | Placement impacts sizing. A prominent back design may need a transfer size of 16″ x 20″, while small logos can use smaller dimensions. |

| Proportion and Balance | Choosing a size that fits the garment’s overall look is crucial. Oversized designs can overwhelm smaller garments, while tiny prints on larger items can look out of place. |

| Standard Sizes | Common transfer sizes include 8″x10″ for small logos, 11″x14″ for versatile designs, and 16″x20″ for large prints. |

| Testing | Experiment with different sizes on various fabrics to achieve the best print quality. |

| Software and Design | Utilize graphic design tools like Adobe Illustrator to create and adjust designs before printing. |

| Paper and Ink | Select high-quality transfer films and inks compatible with the chosen transfer size for durability and visibility. |

| Market Trends | Stay updated with new developments in DTF printing technology to maintain a competitive edge. |

Summary

DTF transfer size is a critical factor in custom printing that directly influences the aesthetic appeal and efficacy of your designs. Choosing the right size ensures that your artwork looks sharp and vibrant on various garments. By understanding the relationship between garment type, design placement, and transfer dimensions, you can create impactful designs that resonate with customers. It’s essential to experiment with different sizes, leverage advanced design software, and select high-quality materials to enhance your custom printing projects. With these insights, you can master DTF transfer printing and elevate your apparel designs.