DTF gangsheet builder starts as a practical approach to organizing multiple transfers on a single sheet, unlocking efficiency for brands, studios, and hobbyists who want faster turnaround. A well-implemented DTF gangsheet builder can streamline your DTF printing workflow by consolidating designs into a tight grid with consistent margins, reducing misalignment and minimizing wasted film. From a DTF gang sheet design perspective, the layout governs how color and white ink interact across multiple transfers, so balance and spacing matter as much as the artwork itself. Following gang sheet design guidelines helps you place designs without overlaps, protect critical margins, and ensure reliable press results across different garments. If you’re new to DTF printing or looking to refine your workflow, you’ll gain practical techniques you can apply right away.

In broader terms, this concept can be described as a multi-design layout strategy for heat-transfer printing, a sheet orchestration method that optimizes space and timing. Viewed through an LSI lens, you can rephrase it as a repeatable production blueprint, a plan that coordinates artwork, margins, and color management across the entire sheet. This mindset aligns with the idea of how to create DTF gang sheets, helping teams communicate clearly while preserving the core technique. By applying these principles, you’ll discover DTF transfer printing tips that improve color fidelity on different fabrics, simplify post-press handling, and reduce waste. If you keep templates, standardized file naming, and a documented SOP, you can scale from one project to many, delivering consistent results and faster turnaround.

1) Understanding the DTF gang sheet concept and benefits

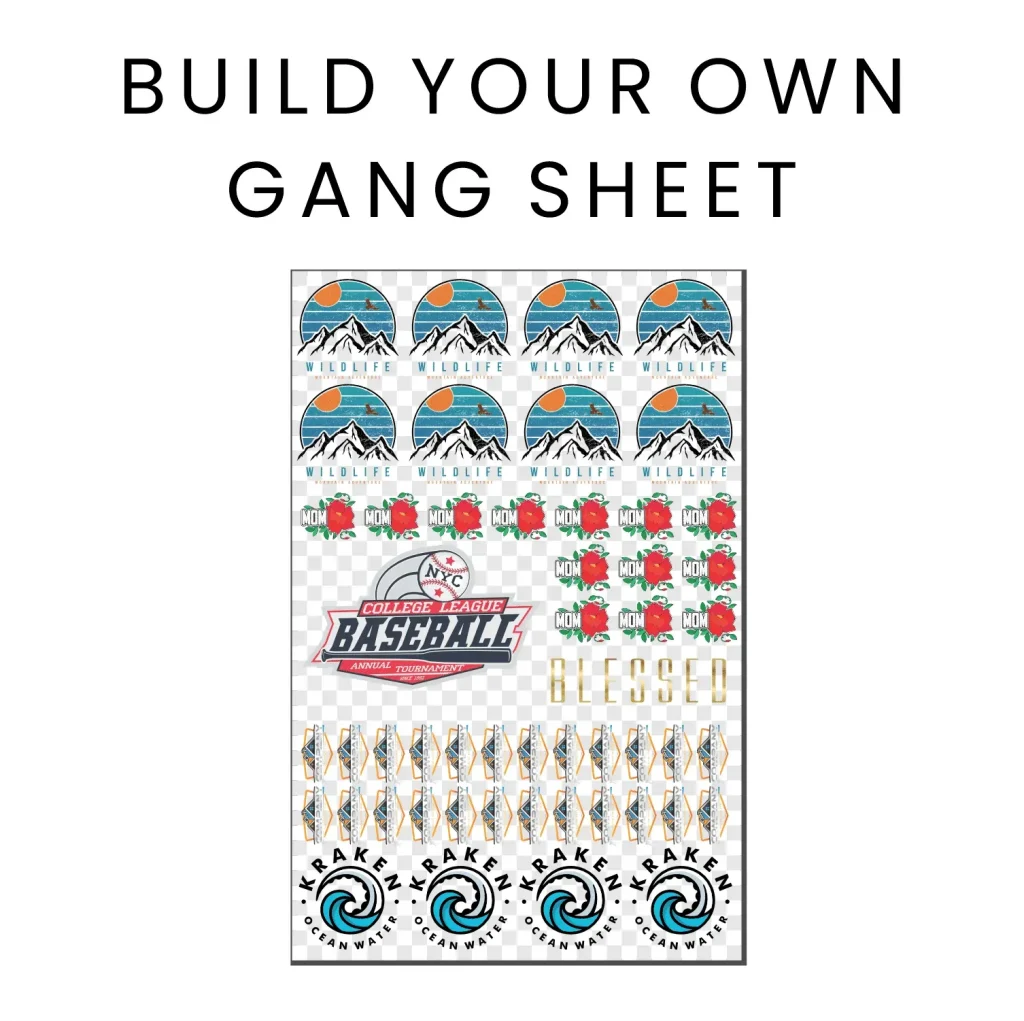

A DTF gang sheet is a single print layout that consolidates multiple designs onto one sheet, enabling faster production and consistent results. This concept sits at the heart of efficient DTF gang sheet design, where planning the spatial relationships between designs becomes as important as the artwork itself. When you approach gang sheets with a builder mindset, you’re optimizing how designs share space, how white ink behaves, and how edging and cut lines translate from screen to garment.

In practice, adopting a well-planned gang sheet workflow reduces setup time, minimizes waste, and increases throughput—especially for orders with similar color palettes or limited color counts. By aligning your DTF gang sheet design with your overall DTF printing workflow, you create repeatable processes that scale from one-off runs to bulk production, while keeping accuracy and consistency intact.

2) Designing a DTF gang sheet: layout, margins, and grids

Effective gang sheet design hinges on thoughtful layout and consistent margins. Designing layouts using a grid system helps prevent overlaps, ensures clean cuts, and simplifies post-print handling. When you apply gang sheet design guidelines, you’ll place designs with uniform gutters and predictable spacing, so each transfer presses cleanly without encroaching on neighboring designs.

Consider the sheet size, printable area, and border allowances as you map designs. Color-critical artwork benefits from predictable alignment and standard margins, which in turn supports accurate post-press registration. Integrating grid-based planning into the design phase minimizes guesswork and makes it easier to reuse layouts as you scale to more designs or different garment types.

3) How to create DTF gang sheets: step-by-step workflow with the DTF gangsheet builder

Creating DTF gang sheets starts with gathering the designs, sizes, and color considerations you’ll combine on a single sheet. This aligns with the how to create DTF gang sheets approach, where you plan the grid, placeholders, and color management in advance. Using a DTF gangsheet builder helps translate that plan into a production-ready file, with consistent artboard sizes, labeled positions, and a standardized export format.

A practical workflow uses templates and predefined naming conventions to streamline repetition. By following a step-by-step method—plan, arrange, proof, export, and test—you ensure each gang sheet adheres to your design guidelines and print specifications. Building this into a repeatable process makes it easier to scale from a handful of designs to dozens without reworking the core layout each time.

4) From file prep to press: a robust DTF printing workflow

A robust DTF printing workflow begins with rigorous file preparation. Calibrated monitors, color-managed artwork, and embedded ICC profiles help ensure that the designs printed on film match the expected output on fabric. When you align the gang sheet with your printing workflow, you’re setting up predictable color behavior, consistent ink densities, and reliable white ink layering across all sheets.

Exporting print-ready files with appropriate color profiles and media settings is essential. Proofing steps—comparing screen previews to test prints, and verifying margins and spacing—reduce surprises on press. This stage also includes preparing the transfer elements and ensuring that the heat press parameters (time, temperature, pressure) align with your transfer film and garment type, so the final result matches the intended design.

5) Color management and quality control: gang sheet design guidelines and color accuracy

Color accuracy is a persistent challenge in DTF printing, making color management a core part of gang sheet design guidelines. Working in a color-managed environment—calibrated displays, ICC profiles, and printer presets—helps maintain predictable reds, blues, and skin tones across sheets. Embedding color profiles in your print files further stabilizes output, ensuring consistent results from batch to batch.

Quality control should run throughout the workflow, with proofs that compare on-screen previews to actual prints. If white underbase is used on dark fabrics, validate opacity and layering within the gang sheet to avoid unintended opacity shifts. Implementing a repetition-friendly color workflow minimizes rework and improves overall reliability of the DTF transfer printing tips you rely on during production.

6) Troubleshooting, optimization, and scalable templates: avoiding common pitfalls and advancing workflow

Even with a solid plan, misregistration, color bleed, or white ink issues can occur. Troubleshooting should start with checking alignment marks, grid spacing, and platen temperature, then moving to reproofing and adjusting margins as needed. Having a scalable, modular template system in place helps you iterate quickly on new orders without redoing the core layout each time.

Advanced optimization includes automating repetitive tasks, such as auto-aligning artwork and batch exporting gang sheets with consistent naming. Dynamic layouts can maximize sheet usage for designs with varying aspect ratios, and documentation (SOPs) ensures accountability across teams. By embracing these practices, you’ll improve throughput, reduce waste, and build a reliable process you can apply to any new design set, always guided by practical DTF transfer printing tips.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it relate to DTF gang sheet design?

The DTF gangsheet builder is the workflow for planning, arranging, and exporting a multi-design sheet. It directly supports DTF gang sheet design by enforcing consistent layouts, margins, bleed, and color management to ensure repeatable transfers and reduced waste.

How does the DTF printing workflow fit into how to create DTF gang sheets using a gangsheet builder?

The DTF printing workflow covers artwork prep, color management, and file export. Using it to guide how to create DTF gang sheets ensures templates, proofs, and printer presets stay aligned across designs for reliable, scalable results.

What are gang sheet design guidelines for a successful DTF gangsheet builder?

Gang sheet design guidelines include consistent grid layouts, uniform margins, safe zones, proper bleed, alignment marks, and planned white ink placements. Following them helps you maximize sheet usage and ensure accurate presses with the DTF gangsheet builder.

What are practical DTF transfer printing tips when using a DTF gangsheet builder?

Tips include maintaining consistent printer settings, planning white ink layers for dark fabrics, matching transfer times to film and fabric, and validating with test sheets. These DTF transfer printing tips help you achieve predictable color and adhesion within the gangsheet workflow.

How do you manage color when planning and exporting DTF gang sheets in the DTF gangsheet builder workflow?

Use color-managed workflows: calibrate monitors, apply ICC profiles, embed profiles in exports, and proof against expected prints. Export print-ready files (PDF/TIFF) with accurate color data to ensure consistent results across gang sheets.

What common pitfalls should you avoid with a DTF gangsheet builder, and how can applying DTF printing workflow and gang sheet design guidelines reduce misregistration and waste?

Avoid misregistration, color bleed, and underbase issues by sticking to gang sheet design guidelines and a disciplined DTF printing workflow. Use reusable templates, precise alignment marks, and regular test prints to minimize waste and keep presses running smoothly.

| Aspect | Key Points (Summary) | Benefits / Notes |

|---|---|---|

| What is a DTF gang sheet and why use one? | A single print layout containing multiple transfers on one sheet; reduces setup time, minimizes waste, and increases throughput. The term DTF gangsheet builder refers to planning and exporting this sheet for accurate reproduction. | Improved efficiency and consistency; faster production for bulk orders. |

| Basics of DTF and gang sheets | DTF transfers use a film to move ink to fabric; designs must align across designs on one sheet; key considerations include sheet size, border allowances, bleed, and transfer order. | Predictable color alignment and simpler postpress steps. |

| Planning your gang sheet: layout, margins, and design compatibility | Use a grid system such as a 4×4 layout with uniform margins; plan garment types, printable areas, number of designs per sheet, color management needs, and margins/bleed/gutter to ensure clean cuts. | Faster setup, accurate spacing, and consistent results. |

| Color management and file preparation | Embed color profiles, export print-ready formats (PDF or TIFF), use vector for text and ensure high resolution (300 DPI) for raster art; maintain color consistency across sheets. | Accurate color reproduction and sharp edges on transfers. |

| Tools and workflow | Design software options include Illustrator, Inkscape, Affinity Designer, or Photoshop; maintain consistent artboard sizes, create proofs, export with color profiles, and use reusable templates with standardized naming. | Reliable, scalable workflow and easier handoffs. |

| Step-by-step: from design to gang sheet | Gather artwork; plan layout; arrange on the gang sheet; apply color management and proofing; export print-ready file; print test sheets; prepare for transfer. | Clear path from concept to production; reduces errors. |

| Printing and heat-transfer: getting the most from gang sheets | Calibrate printer and keep consistent print settings; plan white ink layers; follow transfer times; account for garment variability. | Color accuracy and durable transfers. |

| Troubleshooting and optimization | Common issues include misregistration, color bleed at edges, white ink opacity problems, and material waste; solutions involve rechecking alignment, margins, color management, and using templates. | Fewer press surprises and reduced waste. |

| Advanced tips for a scalable DTF workflow | Create modular templates, automate parts of the workflow, use dynamic layouts, and document SOPs for accountability. | Faster iterations, consistency, and clear processes. |

Summary

DTF gangsheet builder is a strategic approach to planning, designing, and producing multiple transfers on a single sheet that helps brands scale efficiently. A well-structured workflow improves consistency, reduces waste, and speeds production from concept to finished transfers. By focusing on layout consistency, color management, and a repeatable export-to-press process, you can deliver high-quality, repeatable prints for any order. For beginners, start with a small batch to validate results and gradually expand with reusable templates, documented processes, and standardized file-naming conventions. Embracing this mindset empowers you to turn design ideas into reliable, scalable DTF outputs that customers love.