DTF Transfer Size Chart is the blueprint that keeps every design aligned across front, back, and sleeves on garments. In Direct-to-Film printing, precise measurements and standardized templates—like a DTF transfer sizing guide—help ensure consistent results. Knowing DTF print measurements helps translate art from screen to fabric, preventing misregistration. A well-defined size chart captures front back sleeve measurements for each size, reducing guesswork in production. Adopting a robust chart not only improves print quality, but also speeds up workflows across teams.

From another angle, the concept becomes a print-area map or garment decoration template that guides placement across sizes. Using LSI-friendly terms such as print layout grid, zone map, and scalable sizing template keeps the core idea visible while expanding semantic relevance. Think of front print zone, back print zone, and sleeve zone as interchangeable descriptors that feed into a centralized alignment guide and margins system. This approach improves search discoverability by linking related concepts like DTF print measurements and transfer sizing strategies to a cohesive workflow.

1. Understanding the DTF Transfer Size Chart: Foundations, Terminology, and Why It Matters

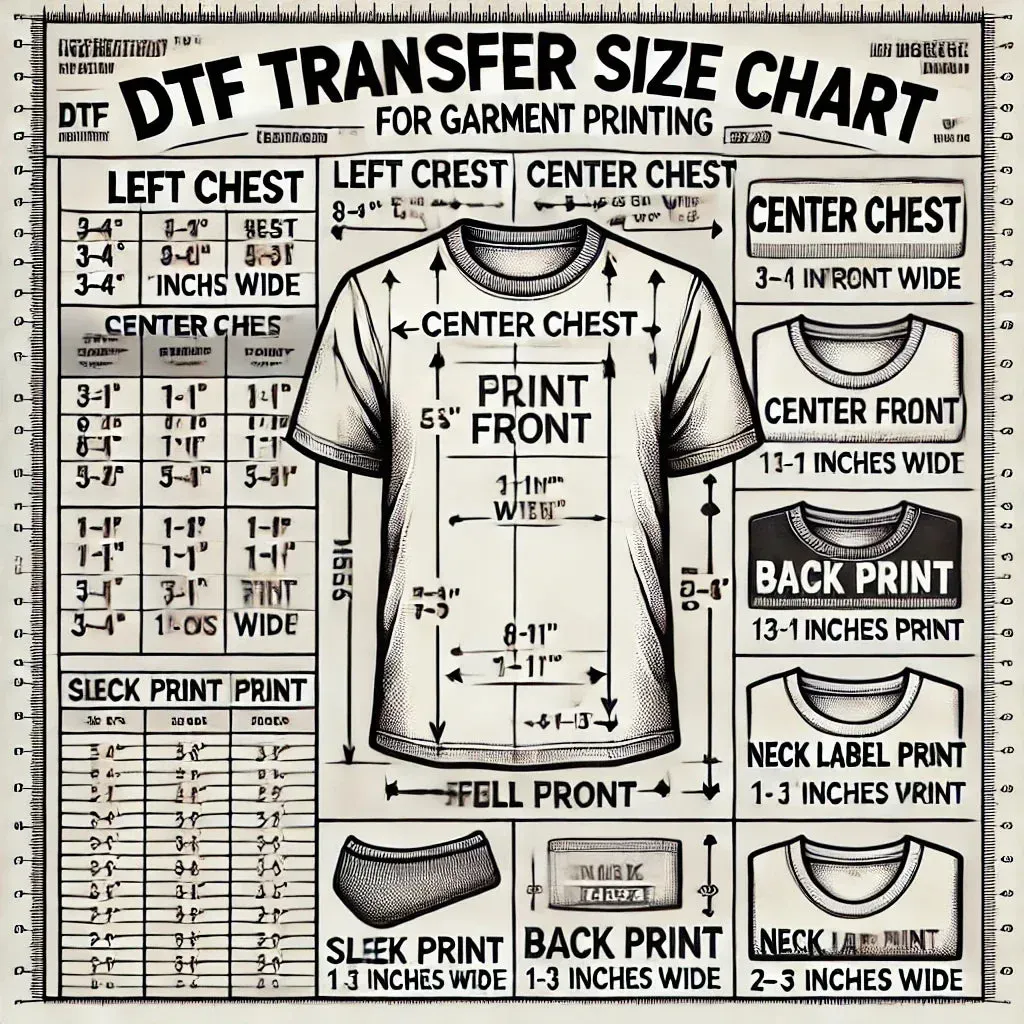

A DTF Transfer Size Chart serves as the blueprint for where artwork lands on a garment, ensuring front, back, and sleeve prints align precisely with each size. By standardizing printable zones, designers can translate concepts into repeatable results, minimizing guesswork and boosting production reliability. In practice, the chart anchors layout decisions to measurable targets such as margins, centerlines, and safe bleed areas, which are essential for consistent outcomes across multiple SKUs.

The chart’s value extends beyond aesthetics; it directly impacts print quality and efficiency. By defining front, back, and sleeve print zones in concrete terms, teams can communicate expectations clearly, prevent misalignment, and reduce rework. When you reference terms like DTF transfer size chart and DTF print measurements, you’re emphasizing a shared framework that supports accurate placement and scalable design across sizes.

2. Translating Garment Measurements into Consistent Print Zones

Turning raw garment measurements into defined print zones requires a systematic approach. Start with a vertical centerline to align front and back designs, then translate chest width, torso length, and back width into corresponding print areas. This process translates real-world garment dimensions into printable coordinates, helping designers place artwork consistently from S through XL.

With front, back, and sleeve zones mapped, incorporate safe margins and bleed allowances so that edge crops do not compromise the final look. DTF print measurements guide how much space to reserve around each zone, ensuring that scaling for different sizes preserves proportion and visual balance across the entire line.

3. DTF Transfer Sizing Guide: Templates, Scaling, and Cross-Size Consistency

A robust DTF transfer sizing guide relies on scalable templates for front, back, and sleeve areas. Start with a baseline size (commonly M) and create proportional templates that can be adjusted for S, L, XL, and beyond without disturbing the central axis. This approach keeps designs aligned and legible when resized, reducing variability between products.

Consistency across sizes is achieved by preserving aspect ratios and maintaining fixed margins relative to the centerline. When used together with a precise scaling workflow, templates enable rapid production planning and provide a repeatable reference for artists, prepress technicians, and production staff alike.

4. Front, Back, and Sleeve Measurements: Practical Ranges for Common Garments

Understanding practical ranges helps you plan realistic print zones. For the front print area, typical widths run from roughly 8 to 12 inches for smaller sizes and extend to 14–16 inches on larger sizes, with vertical measurements adjusted to garment length. These ranges ensure the design sits comfortably on the chest without crowding necklines or skirts of the garment.

The back print area is generally larger, spanning from the shoulder blade down toward the mid-back. Expect back heights of about 12 to 20 inches depending on garment style, with back widths matching the garment’s back width. Sleeve prints vary by length and style, with widths commonly between 3 and 6 inches and lengths from 8 to 28 inches, adapting to short sleeves, long sleeves, or raglan constructions.

5. Minimizing Misalignment: Testing, Bleed, and Calibration in DTF Printing

To prevent misalignment, implement a test-print protocol that checks front, back, and sleeve zones on representative samples. Begin with a test run on a garment of each size to verify alignment, color fidelity, and edge safety margins. Calibration sheets that track color performance and positional accuracy help teams identify drift early before mass production.

Bleed control is critical for reliable results. Include a safe margin around every printable zone (0.25 to 0.5 inches, as a starting point) so edge crops are avoided during transfer. Regularly reviewing DTF print measurements against on-garment samples keeps the process tight and reduces costly reprints.

6. Implementing a DTF Transfer Size Chart in Production: Workflow and Real-World Examples

Bringing a DTF Transfer Size Chart into production requires a clear, repeatable workflow. Start by establishing baseline templates for front, back, and sleeve zones, then scale those templates for every size while preserving the centerline and margins. Place artwork within the defined zones, run test prints on representative garments, and adjust the chart as needed based on results.

A real-world example shows how a small brand benefits from a structured size chart. By measuring samples, creating size-specific templates, and applying safe margins, they achieved consistent alignment and faster throughput across multiple sizes. The outcome is fewer reprints, tighter quality control, and a scalable path for expanding their DTF printing line.

Frequently Asked Questions

What is a DTF Transfer Size Chart and how does the DTF transfer sizing guide support consistent prints?

A DTF Transfer Size Chart defines the printable zones for front, back, and sleeve areas on a garment. When paired with a DTF transfer sizing guide, it ensures consistent placements across sizes, reduces misalignment, and speeds production by providing repeatable templates and safe margins.

How are DTF print measurements and the DTF Transfer Size Chart used to plan front, back, and sleeve placements?

DTF print measurements are fed into the DTF Transfer Size Chart to set precise printable zones. By mapping front widths, back heights, and sleeve lengths to standard sizes, you create scalable templates with a central axis, consistent margins, and predictable alignment across garments.

Why are accurate front back sleeve measurements essential in the DTF Transfer Size Chart?

Accurate front back sleeve measurements ensure designs land where intended; misreports can cause distortion or misalignment. The DTF Transfer Size Chart standardizes these zones across brands and sizes, preserving artwork integrity from small to plus sizes.

Can I reuse the same front and back design across sizes using the DTF transfer sizing guide?

Yes. Reusing a design across sizes is feasible if you scale the printable zones proportionally using the DTF transfer sizing guide. Maintain the centerline, margins, and aspect ratio to keep the artwork visually correct on all sizes.

What steps are involved in measuring a garment for the DTF Transfer Size Chart and creating printable zones?

Steps: lay the garment flat, measure front width and length, back width, and sleeve length; add bleed margins (0.25–0.5 inches); translate these measurements into your design software, create front/back/sleeve templates, and test with a sample garment to verify alignment.

How should I handle garment variability and shrinkage when following the DTF Transfer Size Chart and DTF print measurements?

Account for brand differences and fabric shrinkage by testing on washed and unwashed samples, applying a shrinkage multiplier if needed, and adjusting margins or zone placements in the DTF Transfer Size Chart. Use calibration sheets and repeatable templates to maintain consistency across batches.

| Topic | Key Points |

|---|---|

| What is a DTF Transfer Size Chart | A template that defines printable zones for front, back, and sleeves and translates inches or centimeters into garment measurements to guide artwork placement. |

| Why this chart matters for DTF printing | Sets consistent print zones across sizes; reduces misalignment during transfer; improves garment-to-garment consistency; helps plan artwork with safe margins and bleed areas; speeds up production by providing a repeatable reference. |

| Front, Back & Sleeve measurements explained | Front print area: typical widths 8–12 inches for smaller sizes, up to 14–16 inches for larger sizes; vertical space ~6–14 inches. Back print area: larger, heights ~12–20 inches; widths mirror back; sleeve area: 3–6 inches wide, 8–28 inches long. |

| How to measure a garment for the chart | Lay garment flat; measure front width armpit-to-armpit; front length shoulder to hem; back width across back; sleeve length/area; note armhole depth and shoulder width; add 0.25–0.5 inch bleed around zones. |

| Translating measurements into design work | Create grid/templates for standard sizes (S, M, L, XL); establish a vertical centerline; set baseline margins; build scalable templates that preserve aspect ratio. |

| Practical tips for using the DTF Transfer Size Chart | Start with a baseline (e.g., M); account for garment variability and shrinkage; use consistent units; perform test prints to calibrate margins and alignment. |

| Applying the size chart to your design workflow | Create baseline templates for front, back, and sleeves; scale per size while preserving centerline and margins; place artwork within defined zones with safe margins; test prints on each size; update templates as needed. |

| Common pitfalls and how to avoid them | Inconsistent units or rounding; garment variability; overlapping zones; neglecting shrinkage; skipping test prints — always test multiple sizes before mass production. |

| Tools and resources to support the DTF Transfer Size Chart | Design templates; garment measurement guides; print calibration sheets; software alignment guides, centering tools, and grid snapping features. |

| Case study: applying the DTF Transfer Size Chart to a new tee line | Front zone: 12″x9″ (size M); back: 14″x18″; sleeve: 4″x24″; post-measurement templates and safe margins; XL showed minor back misalignment, adjusted with vertical size-based shift; resulting in consistent prints across sizes. |

| Frequently asked questions | Different charts for hoodies or long-sleeve shirts? Yes; create separate templates. Sleeve precision: 1/8″–1/4″ generally; can be tighter for large prints. Front/back designs can be reused if zones scale proportionally and margins are maintained. For pre-shrunk garments, test on washed and unwashed fabric to validate accuracy. |

Summary

DTF Transfer Size Chart is a cornerstone of consistent, high-quality prints. By defining precise front, back, and sleeve measurements and translating them into scalable templates, you create a repeatable process that reduces misalignment, speeds production, and improves overall garment appearance. Measure garments carefully, build robust templates, and test prints to validate the chart’s accuracy. A well-implemented size chart supports consistent branding across product lines and enables scalable growth in your DTF printing program. With attention to margins, bleed, and garment variability, you can deliver reliable results batch after batch, delighting customers with accurate, shop-ready transfers.